Welcome to our

Laser Research and Fabrication Lab

We conduct state-of-the-art research in the field of laser processing for photovoltaics. Key fundamental areas of laser research include both n-type and p-type laser doping of silicon, selective ablation of dielectric materials and micromachining of silicon surfaces and wafers. With access to several laser sources and beam delivery options, the laser processing research team are developing laser processes that can be integrated into industrially feasible solar cell fabrication sequences.

Contact

Facilities

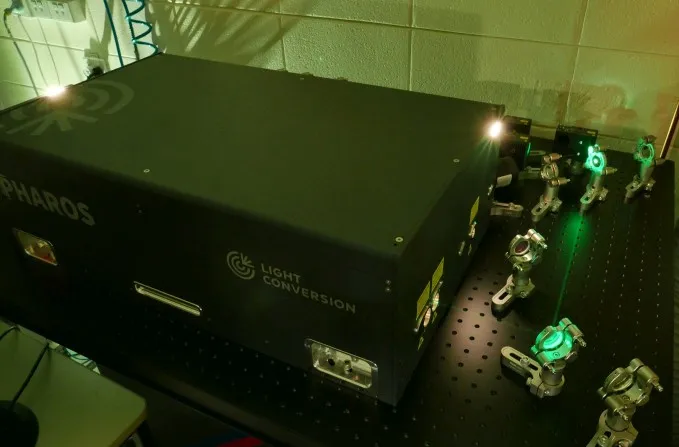

Pharos Femtosecond laser.

The variable femto- and picosecond laser operates at UV, Green, and Infrared wavelengths for a wide range of laser processing and ablation tasks. Achieves µm accuracy with the high-precision four-axis stage over a scan area of 200 mm x 200 mm.

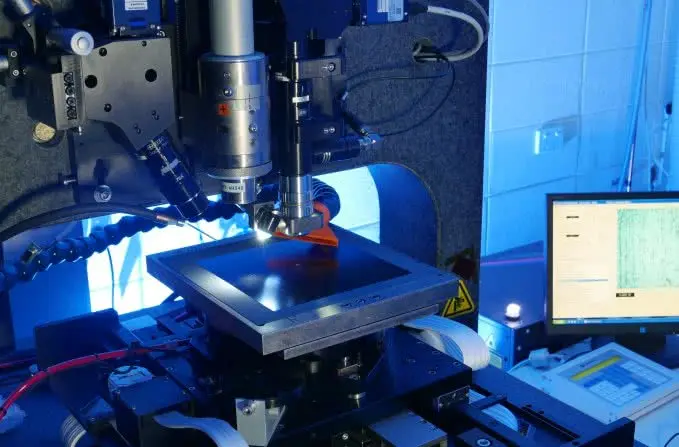

System detailsCoherent Excimer UV laser.

Our variable UV nanosecond laser completes tasks such as laser doping and laser ablation. Achieves µm accuracy with the high-precision four-axis stage over a scan area of 200 mm x 200 mm.

System details

EOLITE Lasers PyroFlex 25.

Tuneable nanosecond laser for laser doping and laser scribing with high-precision four-axis stage and high-performance galvanometer scanner achieves µm accuracy at high speed over a scan area of 200 mm x 200 mm.

System detailsIPG Photonics nanosecond laser.

Our workhorse for laser cutting and scribing with high precision four-axis stage and a high-performance galvanometer scanner for repeatable µm accuracy at high speed.

System details

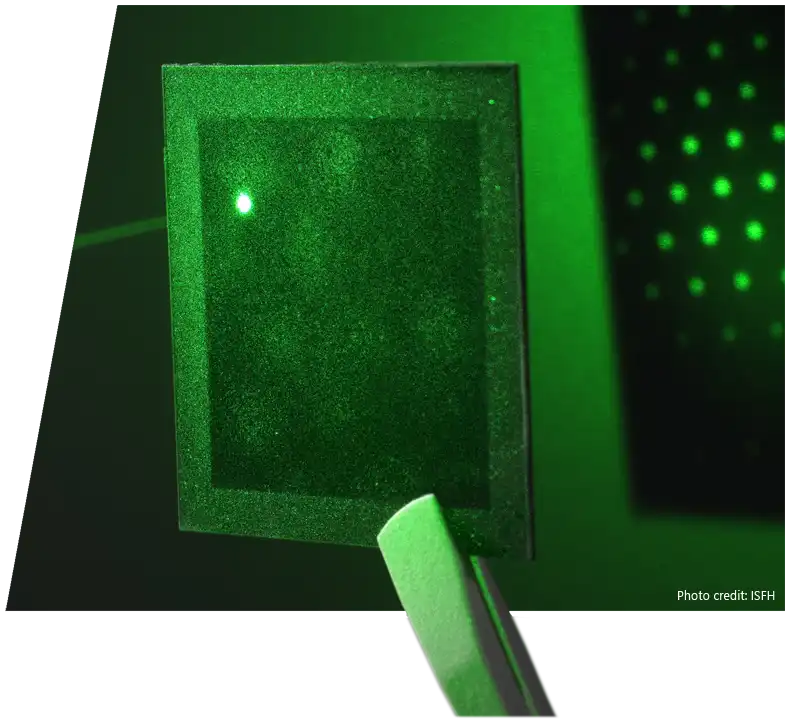

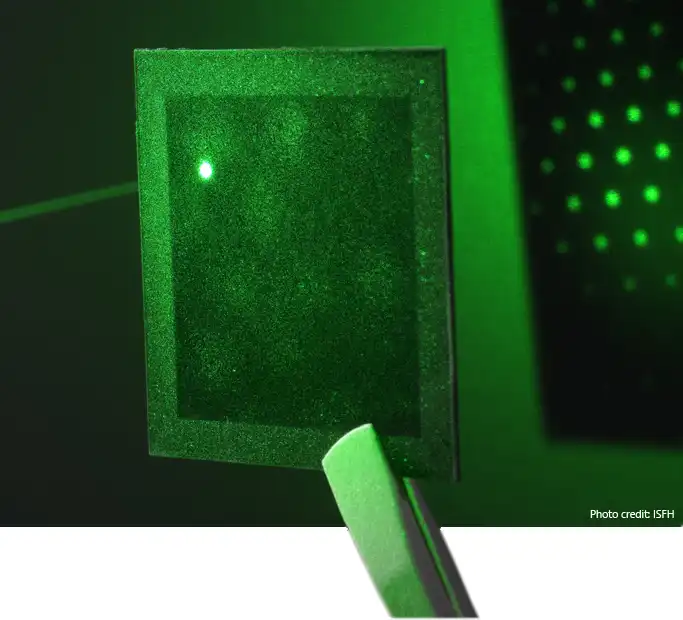

Access

Characterisation of laser processed samples is a critical part of the research focus, being required in particular in order to optimise laser parameters and ensure desired characteristics (eg deep, homogenous doping with easily contacted surfaces) with minimal induced silicon damage can be achieved. A range of characterisation methods are utilised, including sheet and contact resistivity analysis, SIMS and ECV for dopant profiling, SEM for surface and dopant imaging, photoconductance lifetime analysis and photoluminesence imaging (PL) for extraction of surface quality parameters, along with and micro-PL techniques.

Access to the ANU PV laser laboratories is available to qualified researchers from anywhere subject to the following restrictions.

- All users must receive the appropriate training to use the equipment as set out in the Laboratory Procedures.

- Users will be subject to the laboratory standard supervision and condition of use.

- If a researcher wishes to use an item of equipment frequently then a cost recovery procedure may be implemented to recover marginal operating costs. This will be on a case by case basis and will depend on the cost of operating and maintaining the particular item.

- If an item of equipment is heavily used then access will be allocated as follows.

- Equipment purchased by ANU: preference to ANU researchers, ACAP researchers, others

- Equipment purchased with ACAP funds: preference to ACAP researchers, others

- Fair and equitable access will be arranged on a case by case basis taking into account the difficulties associated with travel from other institutions. Send Booking Request

Contact

For questions regarding collaborations and accessing the PV laser facilities, please contact Dr Marco Ernst.

Phone Number

+61 (02) 6125 0080Address

Engineering Building #32, North RoadThe Australian National University

Canberra ACT 2600